Ideal plasma source performance

How to choose the right power of the plasma source for CNC plasma Raptor? We will be happy to help you choose the optimal performance of the CNC machine. In order to determine the ideal configuration of the plasma cutting machine, in addition to the size of the work surface, the required strength of the material being cut is also key. With higher power of the plasma source, the possibilities of maximum strength of the machined sheet metal increase. CNC plasma can be equipped with sources with different power according to use, and the power in this case is indicated in Amps.

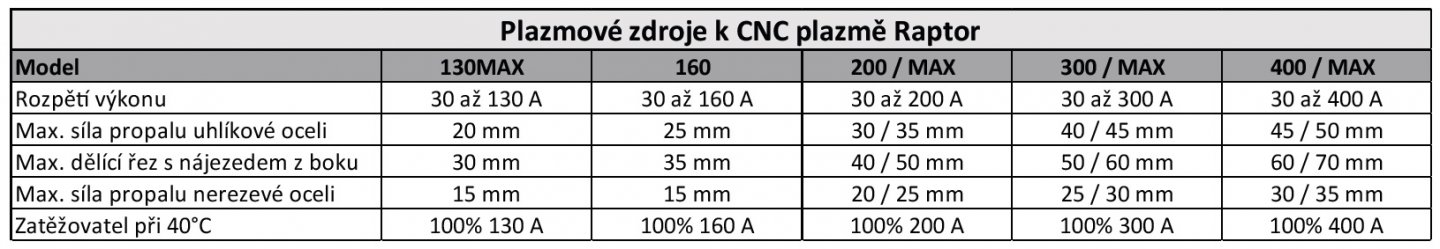

Ideal performance also affects the quality of the cut, especially on thicker materials. For weak sheets, it is necessary to regulate the power of the source and higher Amperes do not have a direct effect on the quality of the cut of the weak sheet. In addition to the performance of the plasma source, the quality of the cut is primarily determined by the plasma torch. We recommend always using water-cooled torches on CNC plasma, which have a significantly longer service life of consumable parts. Metal materials such as classic steel, stainless steel or aluminum can be cut with a plasma router. Below we present an indicative table of the possibilities of various performance variants of plasma sources that can be part of the delivery with a CNC plasma.

Basic plasma sources use clean compressed air for the burning process. Higher series of sources have the option of a gas console, which is able to distribute also technical gases such as oxygen or nitrogen or gas mixtures for burning with a plasma cutting machine. With the use of oxygen, it is possible to achieve better productivity and cut quality. Nitrogen is recommended for firing stainless steel to minimize burning of the material around the cut. Stainless steel can also be cooled with a water emulsion. The values given are for efficient burning and the MAX version uses technical gases.

If you are interested in Raptor CNC plasma, we will be happy to recommend the appropriate power source for your application. At the same time, we recommend a personal inspection of the entire equipment, including a demonstration of your material. Plasma cutting has its limits and the quality of the cut cannot be reached to the same level as with a CNC laser cutting machine. We will personally describe the differences to you and show you samples of firings from both technologies.