CNC laser cutting machine

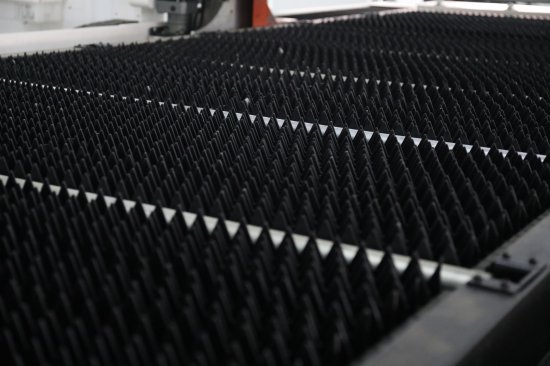

Some time ago, we started building a CNC laser cutting machine Raptor. The customer's requirement is also to equip the CNC laser with a fourth cutting axis, where the customer will cut pipes with a diameter of up to 220 mm. We build the laser cutting machine on a robust construction of a steel weldment, which we then have machined on a large portal milling machine. The fiber laser has an output of 3 kW and is equipped with a laser process head with autofocus. The working space has dimensions of 3050x1550x200 mm. The surface consists of close-up honeycombs and the portal of the CNC laser cutting machine has an aluminum construction, which reduces its weight and increases the speed of movement of the working head of the laser machine. The fiber from the fiber laser is guided by a wide cable chain with sufficient clearance.

I am interested in a CNC laser cutting machine

Design of a laser cutting machine

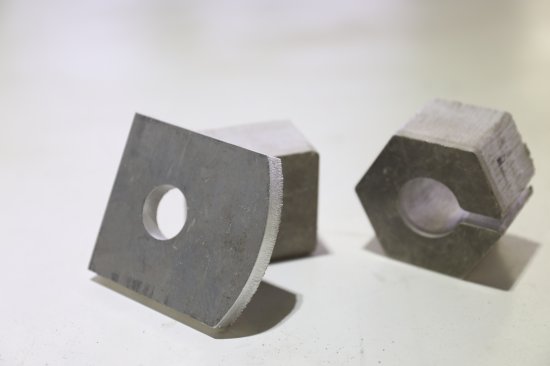

After machining the entire structure, including the portal of the laser cutting machine, we fitted the bed with a linear guide and very fast Panasonic servomotors. The acceleration of the CNC laser reaches its maximum value of 1.5 G and the positioning speed can be up to 140 meters per minute. It is a very productive laser cutting machine and therefore has two interchangeable tables, where you do not have to waste so much time loading and unloading material from the cutting laser. The lightweight process head of the LightCutter laser machine has automatic focus focusing and achieves a beautifully clean cut even with smaller holes. The customer with this CNC laser cutting machine wanted to cut mainly stainless steel, aluminum but also copper. However, the pipes are only made of stainless steel. With a fiber laser power of 3 kW, it is also possible to cut 20 mm thick sheet metal from classic steel. The entire laser machine is covered for safety reasons and there are optical barriers at the exchange tables. At Raptor Technologies, safety is always a priority.

After completing the machine, we arranged a handover test with the customer and everyone was satisfied with the result. We have achieved this using quality components and laser technology from the world's leading manufacturer. Thanks to high-quality workmanship, we can provide a three-year warranty on all our laser cutting machines. The advantage is also mainly in the compactness of the entire design, where all the technology, including the laser source and cooling, is located just inside the CNC laser. To facilitate the work of operating the cutting machine, we have equipped this laser with an automatic lubrication system for all travels. The operator of the laser cutting machine only monitors the lubricant level.

Control interface of CNC laser cutting machine

As it is a very modern and precise laser machine, its operation is also very intuitive, advanced and has many clever features. The complete basis is the automatic placement of blanks on the sheet metal to minimize metal waste from the laser cutting machine. A great function for operating the cutting laser is the automatic sheet metal search, where the machine itself is able to recognize the size and location of the sheet and adapt the burning program accordingly. The whole process is monitored by the operator of the cutting machine through another monitor, where the real course of cutting can be seen through the camera image. The laser machine is equipped with several anti-collision sensors which, in the event of a collision or only its possible occurrence, alert the operator through the monitor and he can react in time. Find out more about the sophistication of CNC laser cutting machines from the Raptor Technologies workshop. We will be happy to show you everything and prepare a tailor-made offer.