CNC machine tools

CNC machine tools

The term machine tool includes a specialized machine for machining mainly metals, but these machine tools are also suitable for wood, plastic, ceramics, glass and others. Together with the time consuming precision and speed of production processes and the lack of qualified machine tools, a solution in the form of computer control - ie CNC machine tools - was implemented in these machines. The key to achieving the desired results is the machine control system and precise processing guaranteeing machining accuracy. For machine tools, we can distinguish two main concepts, namely turning and milling. In turning, the rotating workpiece is machined against the cutting tool and the final product is created. In milling, the machining process is reversed and the workpiece is static and the milling cutting tool processes it into the final state by movement.

I am interested in a CNC machine tool

Lathes and milling machines

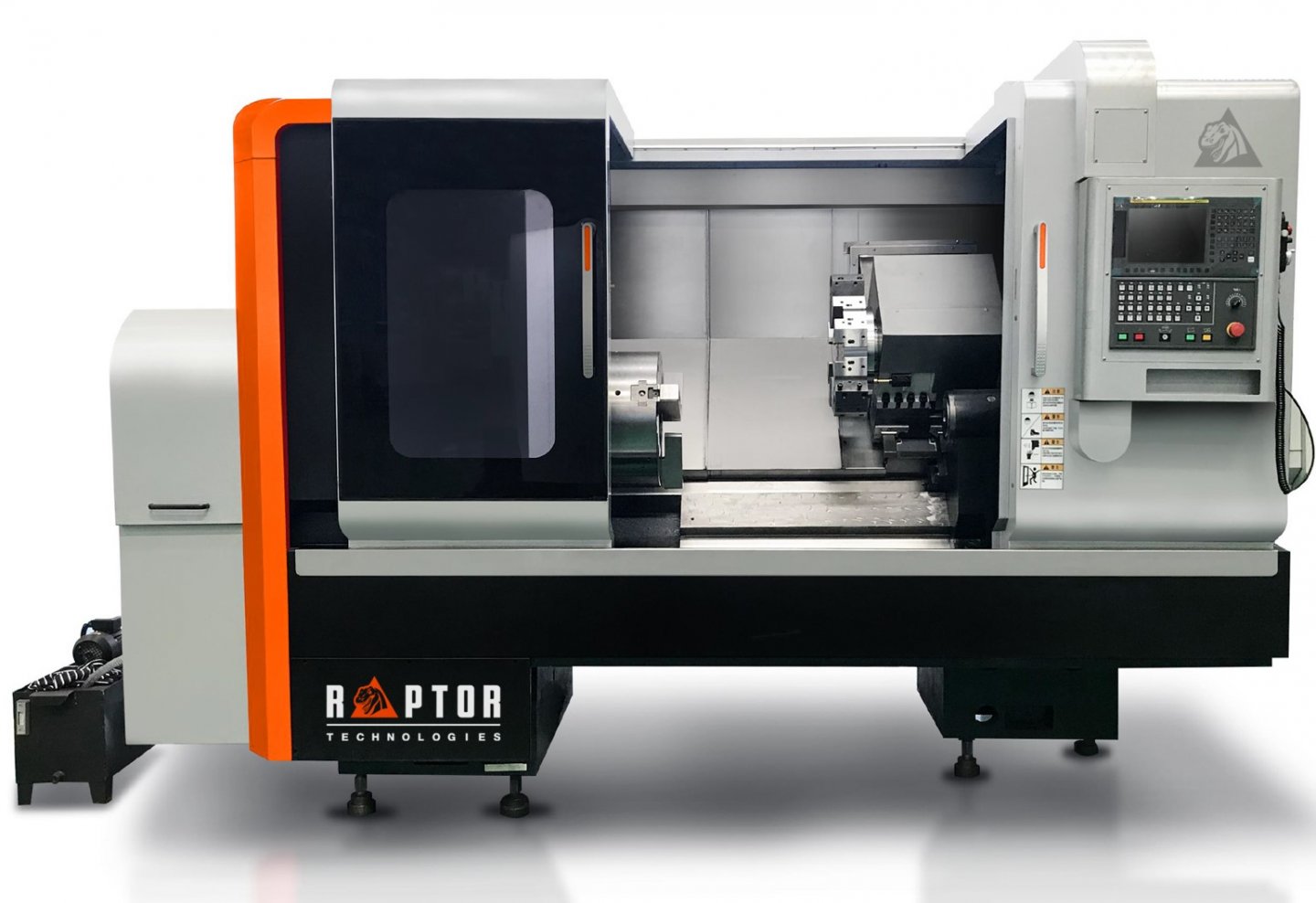

Turning machines can be called as a CNC lathe, long-turning automatic machine, CNC turning center, multi-spindle lathes, CNC multifunctional turning machine and as a machining center in more complex designs. In such cases, CNC machine tools can turn and mill at the same time. The workpiece is clamped to the lathe using a chuck, which can be hydraulic for easier handling. Against the chuck is a so-called tailstock, which serves as a support for the workpiece. The spun material is machined with a cutting tool. The tools may have replaceable parting inserts. CNC lathes can be metalworking or woodworking.

Milling machines are most often used as CNC milling machine, CNC vertical or horizontal milling machine, CNC horizontal but also vertical center, CNC horizontal boring machine and again for complex multi-purpose devices that are multi-purpose, and we can therefore call them CNC machining centers. Frequent confusion of terms occurs between the milling machine and the milling machine. Milling machine is a designation for a machine tool and a milling machine is the name of a tool suitable for milling. The CNC milling machine works on the opposite principle than the lathe. The workpiece is clamped firmly on the working surfaces of the milling machine and the cutting tool is positioned by the machine relative to the workpiece. CNC milling machines can be three-axis in the basic configuration. They have more axes for machining the entire workpiece in one fixture, and now five-axis CNC milling machines are very popular. You can also mill various materials such as metals (steel, aluminum, copper, brass) or plastics and glass.

Machining centers

We can consider complex four and multi-axis machine tools as machining centers, which are able to perform several operations at the same time and combine possible milling with turning. Most of these CNC machines are equipped with automatic tool changers to minimize operator intervention. Depending on the position of the workpiece, the machining centers can be vertical or horizontal. Thanks to the use of multiple axes, it is already possible to produce products of all shapes or sizes in the machining center.

If you choose one of the CNC machine tools, we can advise you based on your needs and your application. We will recommend a suitable machine and prepare a price offer for you, including all required accessories. Do not hesitate to contact us at any time. We are a Czech manufacturer and we are engaged in the development, production and sale of machine tools to order.

Raptor Technologies